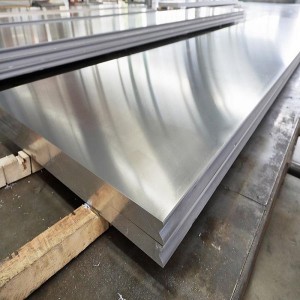

Product Description

Lub ntsiab alloying ntsiab ntawm 6061 txhuas pas nrig yog magnesium thiab silicon, thiab tsim Mg2Si theem.Yog tias nws muaj qee qhov manganese thiab chromium, nws tuaj yeem ua rau tsis zoo ntawm cov hlau;Qee zaum ib qho me me ntawm tooj liab lossis zinc ntxiv los txhim kho lub zog ntawm cov hlau tsis muaj qhov txo qis nws cov corrosion kuj;tseem muaj me me ntawm cov khoom siv hluav taws xob.tooj liab los cuam tshuam qhov tsis zoo ntawm titanium thiab hlau ntawm hluav taws xob conductivity;zirconium lossis titanium tuaj yeem kho cov nplej thiab tswj cov qauv recrystallization;txhawm rau txhim kho machinability, txhuas thiab bismuth tuaj yeem ntxiv.6061-T651 yog lub ntsiab alloy ntawm 6 series alloy, thiab nws yog cov khoom zoo aluminium alloy khoom uas tau dhau los ntawm kev kho cua sov thiab ua ntej ncab.Txawm hais tias nws lub zog tsis tuaj yeem muab piv nrog 2XXX series thiab 7XXX series, nws cov magnesium thiab silicon alloys muaj ntau yam ntxwv thiab kev ua haujlwm zoo heev, zoo heev vuam cov yam ntxwv thiab electroplating, zoo corrosion kuj, siab toughness thiab tsis deformation tom qab ua, cov khoom ntom ntom tsis muaj qhov tsis xws luag thiab yooj yim polish, yooj yim rau xim zaj duab xis, zoo heev oxidation nyhuv thiab lwm yam zoo heev yam ntxwv.

6063 txhuas pas nrig yog ib qho tsis tshua muaj alloyed Al-Mg-Si series siab plasticity alloy.Nws muaj ntau yam tseem ceeb nta:

1. Muaj zog los ntawm kev kho cua sov, muaj kev cuam tshuam siab toughness, thiab insensitive kom ploj.

2. Nrog rau cov thermoplasticity zoo heev, nws tuaj yeem extruded ntawm kev kub ceev mus rau hauv complex, nyias-walled thiab hollow profiles los yog forged rau hauv forgings nrog complex qauv, dav quenching kub ntau, tsawg quenching rhiab heev, tom qab extrusion thiab forging demoulding, ntev li ntev raws li qhov kub thiab txias. yog siab tshaj qhov quenching kub.Nws tuaj yeem quenched los ntawm cov tshuaj tsuag dej los yog dej nkag.Thin-walled qhov chaw (6<3mm) kuj tuaj yeem ua cua quenched.

3. Zoo heev vuam kev ua tau zoo thiab corrosion kuj, tsis muaj kev ntxhov siab corrosion cracking nyiam.Ntawm cov tshav kub-kho tau-ua kom muaj zog aluminium alloys, Al-Mg-Si alloys tsuas yog cov alloys uas tsis pom muaj kev ntxhov siab corrosion tawg.

4. Qhov saum npoo tom qab ua tiav yog du heev thiab yooj yim rau anodize thiab xim.

Tshuaj muaj pes tsawg leeg thiab txhua yam khoom ntawm 6061 txhuas pas nrig

| Al | Si | Cu | Mg | Zn | Mn | Cr | Fe | Ti |

| Nyiaj pab | 0.4-0.8 hli | 0.15-0.4 hli | 0.8-1.2 hli | 0.25 | 0.15 | 0.04-0.35 dr hab | 0.7 ua | 0.15 |

| Tensile zog σb | ≥180MPa |

| Yield zog σ0.2 | ≥110MPa |

| Elongation δ5 (%) | ≥14 |

| Elasticity coefficient | 68.9 gvp |

| Qhov kawg bending zog | 228 MPa rau |

| Bearing Yield zog | 103 MPa siab |

| qaug zog | 62.1 MPa rau |

| Qauv loj | Txoj kab uas hla: ≤150 |

Tshuaj muaj pes tsawg leeg thiab txhua yam khoom ntawm 6063 txhuas pas nrig

| Al | Si | Cu | Mg | Zn | Mn | Cr | Fe | Ti |

| Nyiaj pab | 0.2-0.6 hli | 0.1 | 0.45-0.9 Nws | 0.1 | 0.1 | 0.1 | 0.35 Nws | 0.1 |

| Tensile zog σb (MPa) | 130-230 Nws |

| Qhov kawg tensile zog ntawm 6063 | 124 MPa |

| Tensile yield zog | 55.2 MPa rau |

| Elongation | 25.0% |

| Elasticity coefficient | 68.9 gvp |

| Bearing Yield zog | 103 MPa siab |

| Poisson tus piv | 0.330 Nws |

| qaug zog | 62.1 MPa rau |

-

6000 Series Aluminium Phaj Sheet-Aluminium Magne ...

-

2000 Series Khoom Txhuas Round Qws

-

Ob Chav Zero Aluminium Ntawv Nyiaj Coil Rau Daim Kab Xev Ntawv

-

1000 Series Aluminium Phaj Sheet-Industrial Pur...

-

Daim iav nyhuv Polished Extrusion Aluminium Profile

-

Stucco Embossed Aluminium Sheet Aluminium Chev