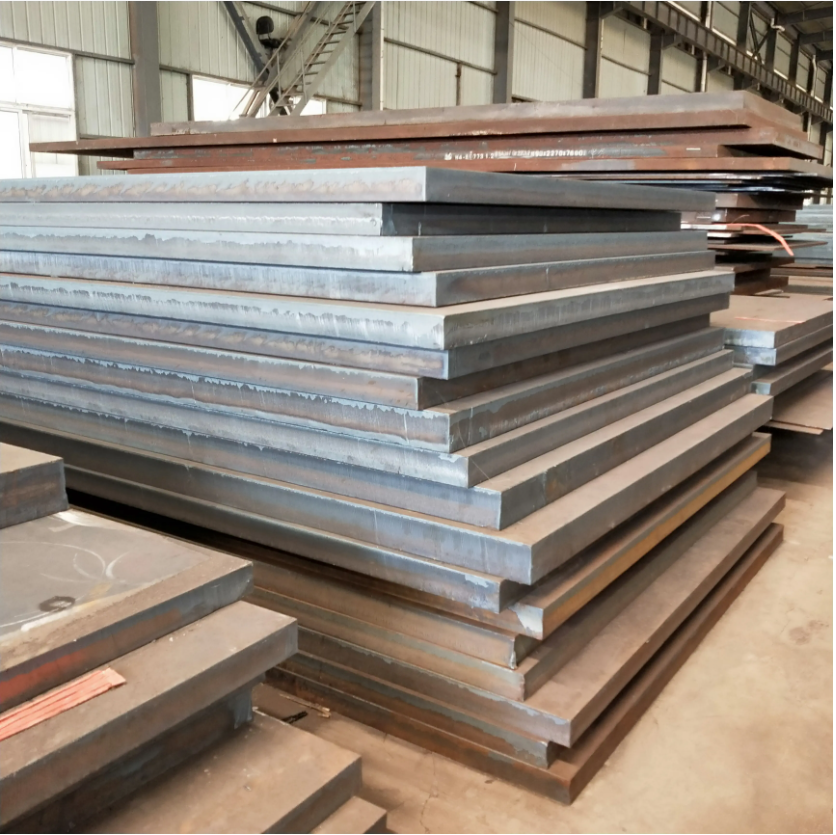

Pressure Vessel Plates Steel daim hlau siv nyob rau hauv kev tsim cov chav boilers, siab hlab ntsha thiab lwm yam structural qhov chaw ntawm siab hlab ntsha.Vim tias hom steel phaj no muaj qee qhov cua siab thiab dej siab, nrog rau kev siv ib puag ncig ntawm qhov sib txawv ntawm qhov kub thiab txias, xws li siab, nruab nrab thiab qis kub, thiab lwm yam.

Khoom taw qhia hloov kho tshaj tawm

(1) Cov ntsiab lus: Ntxiv rau qhov yuav tsum tau muaj lub zog thiab tawv, cov khoom siv kuj tseem yuav tsum tau ua kom zoo ib yam, thiab cov teeb meem tsis zoo yog nruj me ntsis txwv.

(2) Hom: Raws li kev faib tawm ntawm cov khoom, nws tuaj yeem muab faib ua ob pawg: carbon steel daim hlau thiab alloy steel phaj;Raws li kev faib tawm ntawm lub zog, nws tuaj yeem muab faib ua siab, nruab nrab thiab qis siab steel phaj;Corroded steel phaj.

Lub thickness ntawm lub phaj siab yog feem ntau nyob rau hauv thaj tsam ntawm 5 mus rau 200mm, thiab lub sij hawm muab faib ua ob peb thickness specifications.Lub teb chaws cov qauv teev cov ntawv qhia qhov ntau thiab tsawg thiab qhov sib txawv uas tso cai.Cov tsos mob zoo (1) Cov duab ntawm cov hlau phaj: xws li camber, flatness, lub kaum sab xis, thiab lwm yam. (2) Deg defects: Cov defects ntawm cov hlau phaj feem ntau muaj xws li tawg, nti, flattened npuas, impurities, hlwv, pores, nias hlau oxide nplai, thiab lwm yam. Rau kev nyab xeeb vim li cas, lub siab lub nkoj steel daim hlau muaj qhov yuav tsum tau nruj dua ntawm qhov chaw thiab qhov tsis xws luag.Cov teeb meem saum toj no feem ntau tsis tso cai.Txawm li cas los xij, txoj kev tsim nyog raug tso cai raug tshem tawm, thiab qhov chaw tshem tawm yuav tsum tiaj tus.Nws thickness yuav tsum tsis txhob ntau tshaj qhov tso cai sib txawv nyob rau hauv thickness ntawm steel phaj.Interlayers kuj feem ntau tsis tso cai.Chemical composition index:

① Carbon steel phaj: feem ntau kuaj xyuas cov ntsiab lus ntawm carbon, silicon, manganese, phosphorus thiab sulfur.Qee cov pa roj carbon steel kuj muaj qee qhov tooj liab, chromium, nickel, molybdenum, vanadium thiab lwm yam khoom.Ntawm lawv, cov pa roj carbon monoxide yog qhov tseem ceeb los txiav txim siab lub zog ntawm cov phaj steel, uas yog, lub zog ntawm cov phaj steel nce nrog qhov nce ntawm cov ntsiab lus carbon.Cov ntsiab lus carbon ntawm carbon steel phaj yog nruab nrab ntawm 0.16 thiab 0.33%.Manganese thiab silicon kuj muaj txiaj ntsig ntawm kev txhim kho cov khoom siv thiab ua kom muaj zog.Silicon: 0.10 ~ 0.55%, Manganese: 0.4 ~ 1.6%.Qee cov qauv tsis tas yuav tsum muaj silicon thiab manganese rau cov phaj boiler zoo tib yam, thiab tooj liab yog qis dua 0.30%.Lwm cov qauv xws li Nyiv thiab Russia tsis muaj cov ntsiab lus tooj liab.Qee cov hlau zoo muaj chromium (qis dua 0.25%), npib tsib xee (qis dua 0.30%), molybdenum (qis dua 0.10%), thiab vanadium (qis dua 0.03%).Cov tshuaj muaj pes tsawg leeg ntawm boiler steel daim hlau ntawm ntau qib yog qhia nyob rau hauv cov qauv khoom muaj nyob rau hauv Table 6-7-3.

② Tsawg alloy steel phaj: Ntxiv rau cov ntsiab lus ntawm cov hlau, kuj tseem muaj qee yam ntawm molybdenum, chromium, npib tsib xee, vanadium, thiab lwm yam. Muaj ntau qib steel ntawm cov hlau tsis tshua muaj hlau, cov qauv siv ntau dua yog raws li nram no: 1/2 Mo, 1/2Mo-B steel: ASTM A204, JIS G3107;Mn-1/2Mo1/2Mo, Mn-1/2Mo-V, Mn-1/2Mo-1/4Ni, Mn1/2Mo-1/2N i steel: ASTM A302, A533, JIS G3119, G3120;1Cr-1/2Mo, 11/4Cr-1/2Mo, 21/2Cr-1Mo, 3C r-1Mo, 5Cr-1/2Mo, 7Cr-1/2Mo, 9Cr-1Mo: JISG4109, ASTM A387, A533, DIN17155.

③ Quenched thiab tempered high-strength steel phaj: saib ASTM A517, A537, A724, A734, JISG3115.

④ Cov hlau tsis tshua muaj kub: suav nrog carbon steel thiab hlau alloy.Cov tshuaj muaj pes tsawg leeg thiab cov khoom siv kho tshuab tuaj yeem pom hauv ASTMA612, A 662, A735, A736, A738, A203, A645, JIS G3126.

⑤ Stainless hlau: xa mus rau JIS G4304, ASTM A240, AISI13, ΓOCT5632.

Post lub sij hawm: Aug-15-2022